This video is on how to detect cavitation in a hydraulic pump. Before determining whether your pump is cavitating or not, it is important to understand what exactly cavitation is. Cavitation is when the pump inlet vacuum is high enough to cause vapor-filled cavities to form in the fluid. When the fluid is pressurized, these cavities collapse, causing severe localized shock and heat damage to the metal surfaces. The effects of cavitation are readily found on the pump outlet ports, where the air is forced back into the fluid under extreme forces. These forces erode materials, eventually destroying the pump. Another effect of cavitation is interference with lubrication inside the pump. Air pockets get between moving parts, allowing metal-to-metal contact, thus increasing friction and heat. Prior to creating an inlet restriction on this pump, let's get a few background readings while the pump is operating in our normal working conditions. Under normal operating conditions, this pump has a vacuum of three inches of mercury. We're also able to see the pump inlet as well as the pump outlet, our normal operating temperature, and our normal operating pressure, which is around 310 psi. Now, let's create a restriction on the inlet side of the pump in order to determine the effect that cavitation has on the system. Take note of the change in sound that the pump is now making. This agitated sound is created by those now vapor-filled cavities making their way to the discharge side of the pump, forced to implode on their way out. Now, let's take a look at the visual signs of cavitation. On my vacuum gauge, where I started off at 3 inches of mercury, I'm now at almost 16 inches of mercury by the pump inlet line. I can see the vapor making its way through...

Award-winning PDF software

cg-835 Form: What You Should Know

Form CG-835V contains all the data required and more including, requirements for: Inspection and record retention as required by the Merchant Marine Act of 1920. (1) Inspection records (including date, time, date and place of inspection and the ship's identification number), (2) Vessel condition checks (when used), (3) A ship's owner's statement, and (4) Vessel condition monitoring and recording and records (including the vessel's status, location, and the method of monitoring and recording) on the vessel when used. U.S. Coast Guard. FACILITY INSPECTION REQUIREMENTS. 1. Date of Inspection 2. Coast Guard inspection form CG-835V, which will be issued to the master of the vessel (e.g. “CG-835V-master letter”). USCG: New Form CG-835V Vessel Inspection Requirements Apr 6, 2025 — CG-835V Vessel Inspection Requirements is a new supplement to the CG-835 General Form, ‥Vessel Inspection Requirements in which all the required information is now provided. However, this will not replace the existing CG-835G General Form, ‥Vessel Inspection Requirements, nor will it replace the CG-835V supplement to the CG-835 General Form, “Vessel/Facility Inspection Requirements.” The Coast Guard has provided a chart of the differences between the CG-835 General Form, ‥Vessel Inspection Requirements (both CG-835G and CG-835V) and the CG-835J Joint Inspection Form and ‥Vessel Inspection Requirements. The Coast Guard's new CG-835V form incorporates more detailed requirements and more extensive requirement tracking. Coast Guard: New Form CG-835V Vessel Inspection Requirements Apr 6, 2025 — The requirement for a Master Letter for Inspections made with CG-835 is changed. Masters must now ensure that, by issuing a CG-835J Joint Inspection Form, they have the vessel's condition reports, vessel/facility inspection reports, master and station records, and all the required documents to conduct inspections.

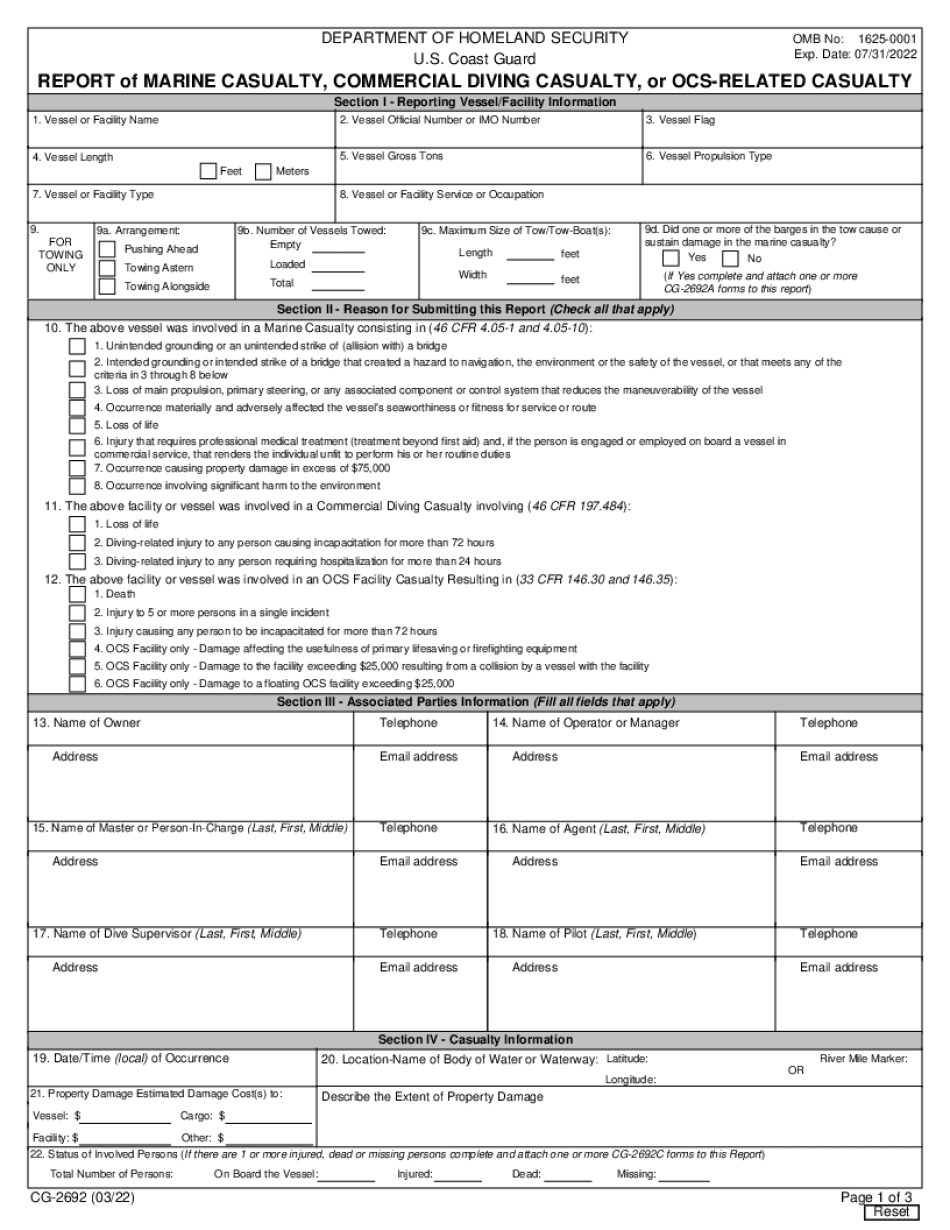

online solutions help you to manage your record administration along with raise the efficiency of the workflows. Stick to the fast guide to do CG-2692 Form, steer clear of blunders along with furnish it in a timely manner:

How to complete any CG-2692 Form online: - On the site with all the document, click on Begin immediately along with complete for the editor.

- Use your indications to submit established track record areas.

- Add your own info and speak to data.

- Make sure that you enter correct details and numbers throughout suitable areas.

- Very carefully confirm the content of the form as well as grammar along with punctuational.

- Navigate to Support area when you have questions or perhaps handle our assistance team.

- Place an electronic digital unique in your CG-2692 Form by using Sign Device.

- After the form is fully gone, media Completed.

- Deliver the particular prepared document by way of electronic mail or facsimile, art print it out or perhaps reduce the gadget.

PDF editor permits you to help make changes to your CG-2692 Form from the internet connected gadget, personalize it based on your requirements, indicator this in electronic format and also disperse differently.

Video instructions and help with filling out and completing Form cg-835